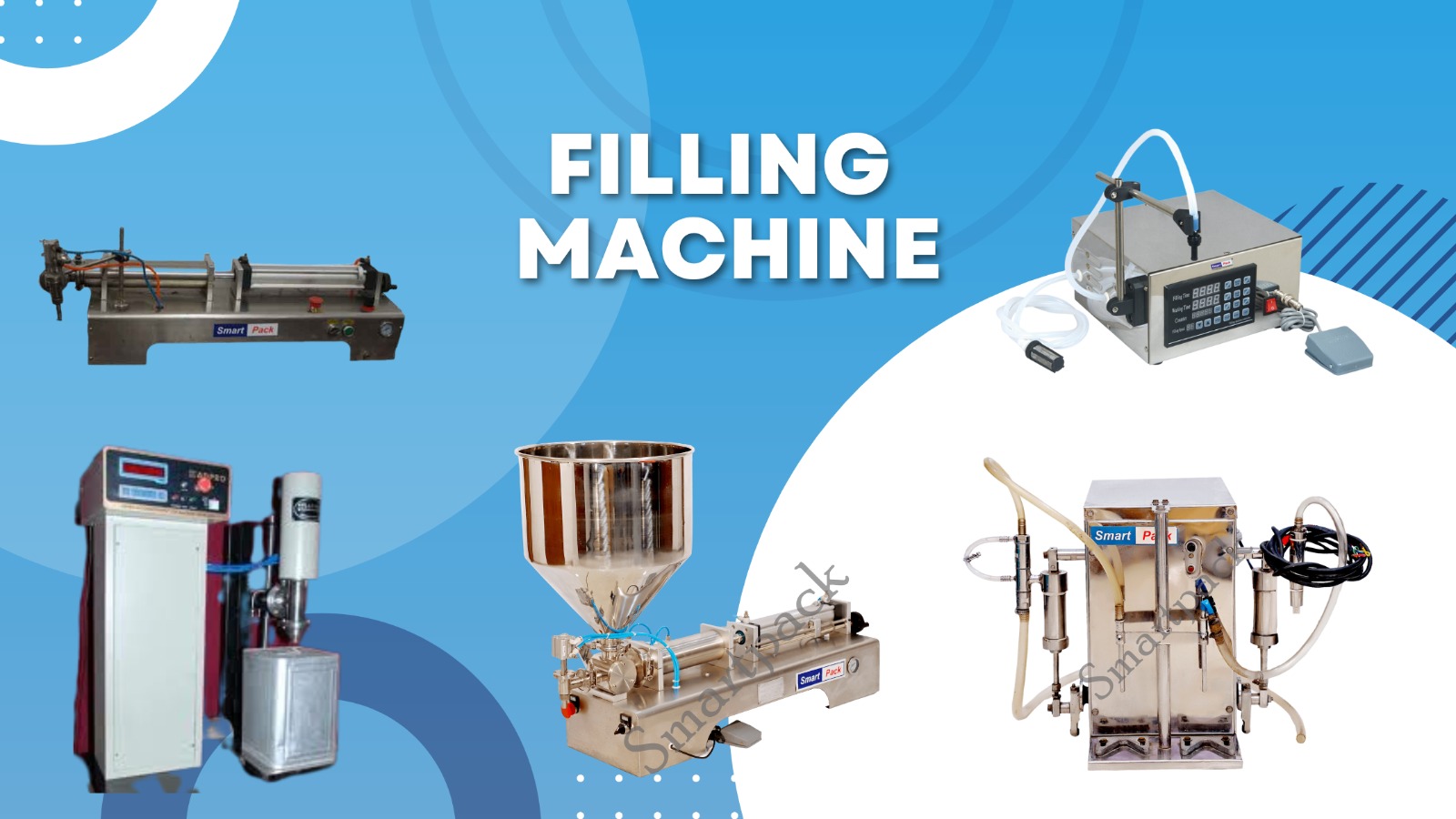

Filling Machine :-

Smart Pack Filling Machine is an advanced equipment designed for filling various types of liquids, semi-liquids, and viscous products into containers with high precision and efficiency. The machine is equipped with smart control systems that allow it to adjust filling volumes and speeds automatically, ensuring accurate and consistent filling. It is widely used in industries such as food and beverage, pharmaceutical, cosmetics, and chemical for filling products like juices, oils, shampoo, lotion, and more. The Smart Pack Filling Machine comes in various models, including piston fillers, rotary fillers, and volumetric fillers, to suit different production needs.

The Importance of Proper Maintenance for Your Filling Machine

Proper maintenance is crucial for ensuring the optimal performance of filling machines. Here are some reasons why:

- Increased lifespan: Regular maintenance can extend the lifespan of the machine by preventing premature wear and tear of critical components.

- Improved efficiency: A well-maintained packing machine can operate at peak efficiency, which translates to higher productivity and reduced downtime.

- Consistent filling accuracy: Regular maintenance ensures that the filler machine maintains its accuracy over time, reducing product wastage and ensuring consistent quality.

- Safety: Faulty or poorly maintained equipment can pose a safety risk to workers. Regular maintenance can identify and fix potential safety hazards.

- Compliance: Regular maintenance helps to ensure that the filler machine complies with regulatory requirements and standards, avoiding costly fines and legal issues.

Types of Smart Pack Filling Machine

Smart Pack Filling Machine is a range of advanced equipment that includes several types of machines designed for fill various types of products. Here are some common types of Smart Pack Filler Machines:

- Piston Filling Machine: This type of filling machine uses a piston to measure and dispense a precise volume of liquid or semi-liquid products into containers. A Piston Filler Machine is a type of volumetric filling equipment that uses a piston to measure and dispense precise volumes of liquid, paste, or semi-liquid products into containers. The machine works by drawing the product into a cylinder, and as the piston moves down, it forces the product out through a nozzle and into the container. The filler volume is determined by the size of the piston, and the accuracy is maintained through adjustments to the stroke length and speed of the piston

- Volumetric Filling Machine: Volumetric Filling Machines use a chamber to hold a specific volume of product, which is then released into the container. A Volumetric Filler Machine is a type of filler equipment that uses a chamber to measure and dispense a specific volume of liquid, paste, or semi-liquid products into containers. The machine works by fill the chamber with the product, which is then dispensed into the container. The filling volume is determined by the size of the chamber, and the accuracy is maintained through adjustments to the chamber size and speed of the filling process.

- Rotary Filling Machine: Rotary Fill Machines use a rotating table to move containers through the filling process, making them ideal for high-speed packing of liquids, pastes, and viscous products. A Rotary Fill Machine is a type of filler equipment that uses a rotating table to move containers through the filling process. The machine works by loading empty containers onto a rotating table, which then moves them through the fill station, where the product is dispensed into the container. The filling station includes one or more nozzles that dispense the product into the container, and the filling volume is controlled by the nozzle’s flow rate and the speed of the table.

- Auger Filling Machine: Auger Filling Machines use an auger to dispense precise amounts of powders, granules, and other dry products into containers. An Auger Filler Machine is a type of filling equipment that uses an auger to dispense precise amounts of powders, granules, and other dry products into containers. The machine works by feeding the product into a hopper, where an auger rotates and moves the product through a tube to the fill nozzle. The auger’s rotation speed and the nozzle’s opening determine the filling volume and accuracy.

- Gravity Filling Machine: Gravity Filling Machines use the force of gravity to fill containers with liquids or semi-liquids, making them ideal for filling thin or low-viscosity products. A Gravity Filler Machine is a type of filler equipment that uses the force of gravity to fill containers with liquids or semi-liquids. The machine works by packing a product tank located above the filler nozzles. As the product is released, gravity forces it through the nozzle and into the container below. The filling volume is determined by the amount of product in the tank and the speed of the filling process.

Why choose Smart Pack Filling Machine

Smart Pack Filling Machines are a popular choice for many industries because they offer several advantages over traditional filling machines. Here are some reasons why you may choose a Smart Pack Filling Machine:

- High Accuracy: Smart Pack Filling Machines are equipped with advanced sensors and controls that ensure high accuracy and precision in the filling process.

- Customizable: Smart Pack Filling Machines can be customized to meet specific requirements, such as filling volume, speed, and product viscosity. This flexibility makes them suitable for use in a wide range of applications.

- Versatile: Smart Pack Filler Machines can handle different types of products, such as liquids, pastes, and powders. They are also compatible with different types of containers, such as bottles, jars, and pouches.

- Efficient: Smart Pack packing Machines are designed for high efficiency and productivity. They can fill large volumes of products quickly and accurately, reducing downtime and increasing output.

- User-Friendly: Smart Pack Filler Machines are easy to operate, with user-friendly controls and interfaces. They also require minimal maintenance, reducing the need for skilled personnel and downtime.